The Importance of Exit Signs with Arrows for Safety and Emergency Preparedness

Introduction

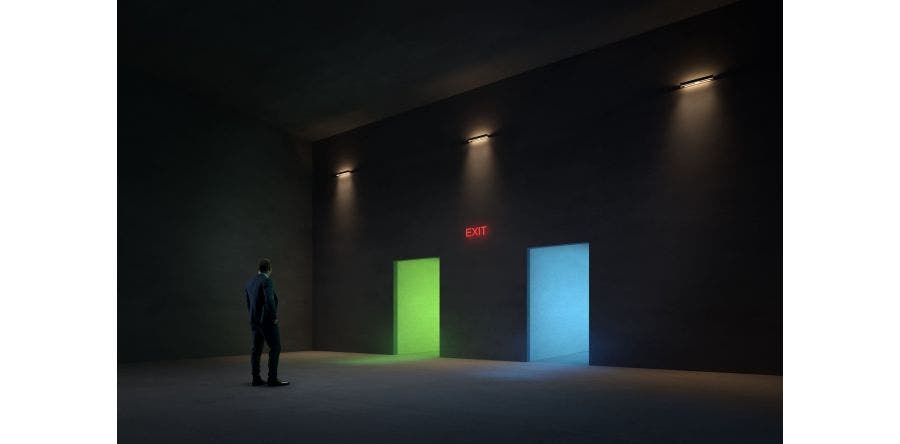

Exit signs play a critical role in safety and emergency preparedness, guiding people to safety in urgent situations. Among the various types of exit signs available, exit signs with arrows are particularly effective in providing clear direction during evacuations. Whether you're in a public building, commercial facility, or industrial setting, these directional signs ensure that occupants can find their way out swiftly, even in high-stress situations.

In this post, we’ll explore the importance of exit signs with arrows, why they are essential for safety, how to choose the right type, and best practices for installation and maintenance. We’ll also cover compliance with safety standards to ensure your signage is up to code.

Why Use Exit Signs with Arrows?

Exit signs are a crucial aspect of safety in any building, but exit arrow signs take it a step further by pointing people in the correct direction to reach the nearest exit. In an emergency, when visibility might be low or when people are unfamiliar with the layout of a building, clear directional guidance is invaluable. Here’s why using exit signs with arrows is important:

1. Clear Guidance During Emergencies

In a chaotic situation, like a fire or earthquake, confusion and panic can make it difficult to navigate. Emergency exit signs with arrows provide unambiguous direction, reducing hesitation and helping occupants make quick decisions.

2. Compliance with Safety Standards

Many safety standards and local building codes require the use of directional arrows on exit signs, especially in complex or large buildings. This compliance ensures that buildings adhere to recognized safety practices, helping to avoid fines or liability issues in the event of an emergency.

3. Assistance in Low-Visibility Conditions

During emergencies, power outages, smoke, or low lighting can obscure traditional exit signs. Illuminated exit signs with directional arrows help maintain visibility, guiding people toward safety even in challenging conditions.

4. Support for Unfamiliar Visitors

Buildings that see frequent visitors—such as shopping malls, hotels, and office complexes—benefit from directional exit signs. Arrows provide intuitive guidance, making it easier for newcomers to follow evacuation routes.

Types of Exit Signs with Arrows

There are several types of exit signs with arrows, each designed to meet specific needs and environments. Here are some of the most common varieties:

1. Standard Exit Signs with Arrows

Standard exit signs feature a simple "EXIT" text accompanied by an arrow. These are typically mounted above doorways, indicating that the exit is straight ahead, or they can be installed with arrows pointing left, right, or downwards, depending on the building's layout.

2. Illuminated Exit Signs with Arrows

Illuminated signs use LED or incandescent lighting to ensure visibility, day or night. These signs often come with a battery backup, allowing them to function even during power outages. Illuminated signs are crucial in settings where visibility is essential, such as theaters, factories, and hospitals.

3. Photoluminescent Exit Signs with Arrows

Photoluminescent signs are glow-in-the-dark options that do not require electricity to remain visible. They absorb ambient light and emit a glow in darkness, making them ideal for areas where power reliability is a concern. These signs are often used as backup to electrical signs.

4. Dynamic Exit Signs with Directional Arrows

Some modern exit signs include dynamic LED arrows that can change direction based on the emergency situation. This adaptability can be crucial in larger facilities where certain routes may become blocked during an incident, allowing for real-time updates to guide occupants safely.

Best Practices for Installing Exit Signs with Arrows

The placement of exit signs with directional arrows is just as important as the signs themselves. Here are some best practices to ensure optimal safety:

1. Install at Key Decision Points

Place exit signs with arrows at every decision point along an evacuation route, such as intersections of hallways or stairwells. This strategic placement helps to guide occupants step-by-step towards the exit without confusion.

2. Mount Above Exit Doors

Mounting signs directly above exit doors is essential for indicating the location of the final exit. Use downward-pointing arrows to signal exits that are directly ahead or below, such as exits leading to staircases or basement levels.

3. Consider Viewing Distance

Ensure that signs are visible from an appropriate distance, taking into account the size of the letters, the size of the arrows, and the height at which the sign is mounted. In larger areas, use larger signs or multiple signs to ensure visibility.

4. Ensure Redundancy with Multiple Signs

In larger buildings or those with complex layouts, it's important to use multiple directional signs along evacuation routes. Redundancy ensures that if one sign is obscured or damaged, others will still provide guidance.

Meeting Safety Standards with Exit Signs

To ensure that exit arrow signs are compliant with safety standards, follow these guidelines:

1. OSHA and NFPA Compliance

In the United States, the Occupational Safety and Health Administration (OSHA) and the National Fire Protection Association (NFPA) have specific guidelines regarding exit signage. For example, NFPA 101 (Life Safety Code) requires illuminated exit signs with arrows in most commercial and public buildings.

2. Local Building Codes

Different regions may have specific requirements for exit signage. Ensure that you are familiar with local building codes, as these codes often dictate the type of signage, placement, size, and visibility requirements.

3. ADA Compliance

In public buildings, the Americans with Disabilities Act (ADA) requires that exit signs be visible and accessible to all occupants, including individuals with disabilities. This can include considerations for height, contrast, and illumination.

Choosing the Right Exit Signs with Arrows

Selecting the correct emergency exit signs with arrows depends on several factors, including the type of building, the environment, and specific safety needs. Here are some factors to consider:

1. Environment

For environments prone to power outages, choose illuminated exit signs with battery backup or photoluminescent options. In areas with low lighting, ensure the sign is bright and clearly visible.

2. Building Size and Layout

Larger buildings with multiple levels or complex layouts benefit from dynamic exit signs or signs with multiple arrows indicating various paths. Smaller buildings may only need standard illuminated signs.

3. Durability

Consider the durability of the materials. Outdoor or industrial environments may require signs that are weather-resistant, impact-resistant, and easy to clean. Choose materials that can withstand wear and tear without losing visibility.

4. Cost and Maintenance

Weigh the initial cost against long-term maintenance. LED illuminated signs might have a higher upfront cost but are energy-efficient and require less maintenance. Photoluminescent signs, while cheaper, need sufficient ambient light exposure to remain effective.

Maintaining Exit Signs with Arrows

Proper maintenance is crucial to ensuring that exit signs function correctly during emergencies. Here are a few maintenance tips:

1. Regular Inspections

Check all exit signs with arrows regularly for visibility and damage. Ensure that the arrows are clearly legible, and the signs are free from obstructions like furniture or décor.

2. Test Backup Lighting

If your directional signs are illuminated, test the backup batteries and lighting systems at least twice a year. Replace any faulty lights or batteries promptly.

3. Clean the Signs

Keep exit signs clean, especially illuminated ones, to avoid any accumulation of dust or debris that might reduce visibility. Use non-abrasive cleaning materials to maintain clarity.

4. Replace Damaged Signs

Signs that have faded, cracked, or sustained other damage should be replaced immediately to ensure they remain effective in guiding occupants during an emergency.

Conclusion

Exit signs with arrows are more than just a compliance requirement—they are essential tools for ensuring safety during emergencies. By providing clear and direct guidance, these signs help save lives in critical situations. Whether you're managing a small business, an industrial facility, or a large commercial building, investing in the right directional exit signage is a fundamental step in emergency preparedness.

Choosing the right type of sign, following best practices for installation, and maintaining compliance with safety standards will ensure that your building is equipped to handle emergencies effectively. A well-planned exit strategy, supported by clear and visible exit signs with arrows, can make all the difference when seconds matter.

Recent Comments